Solution

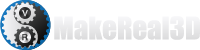

Proactive Design of Maintainability

The Proactive design of maintainability uses similar product information and expert experience information to consider the effects by the relationship between the product's functional structural characteristics and various maintainability factors before designing the functional structure of the product, and constructing the connection relation visualization model of functional structural characteristics and qualitative and quantitative factors of maintainability. It can use the quantitative description of the corresponding relationship to calculate the degree of importance of the structural characteristics of each function and output it to designers as an important design constraint and reference; therefore, improving product maintainability and reducing post-maintenance defects. It can also support product design and maintainability design simultaneously, achieve the correlation between product design and maintainability parameters, the design of maintainability and overall coordination.

It mainly includes the process of proactive design of maintainability, the correlation tool of maintainability and function structure characteristics, maintainability design characteristics factor importance assessment tool and other functions.

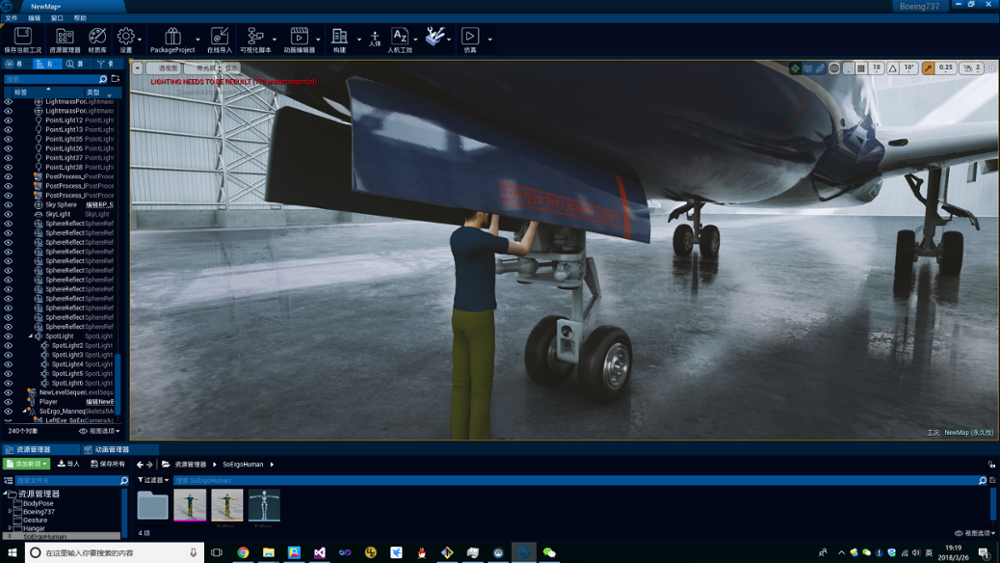

Virtual Simulation Analysis and Verification Assessment of Maintainability

Evaluate the rationality of the maintainability design scheme through the virtual simulation analysis and verification evaluation of each maintainability task in the virtual maintainability scene. It can make full use of the virtual simulation technology's intuitive and interactive features to provide visibility, reachability, and maneuverability verification assessment, and can provide a variety of virtual human visual cone, reachability envelope ball, collision detection and other analyzing tool. The virtual human visual cone detection method is used to perform visual verification, the enveloped ball is used to perform reachability assessment, and the collision detection is used to perform operability assessment.

It mainly includes the process of proactive design of maintainability, the correlation tool of maintainability and function structure characteristics, maintainability design characteristics factor importance assessment tool, and other functions.

Maintainability Allocation and Prediction

At the stage of product development scheme, it provides the basis for the selection of the optimal scheme and optimization of the plan through the maintainability prediction to compare the maintainability level of different schemes. At the product design stage, it discovers the main factors that affects the maintainability of the system through maintainability prediction, finding out the weak links, and taking design measures to improve the system maintainability. The prediction methods provided includes: functional hierarchy prediction method, time cumulative prediction method, and the operational function prediction method.